Soundproofing a Room in Your Home

Now more than ever, people are working from home. People are looking for options for a quiet space and this has created a higher demand for soundproofing and sound reduction. Sometimes it’s to keep the sound of family and/or roommates from interfering their daily work routine. Other times it’s just to block out the sounds around you, such as a busy city street. Whatever the reason more people are looking at ways to reduce the sounds in their homes. There has probably never been a more popular interest in soundproofing a room in your home. I’ll tell you about my soundproofing experiencing and demonstrate the final results by the end of this article.

PART 1 - THE PLAN

Way back in 2008 I moved into a new home that had an unfinished basement. I’d recently been in a band and was a huge fan of playing and learning the guitar. The idea of soundproofing was foreign to me, but I knew that playing guitar, even at low volumes was very intrusive to people around.

So I began researching online the best low cost options that existed for soundproofing a room. My goal was to create a room that would block the sounds of a guitar and keep everyone else sane in my home. Let me walk you through the different stages of my soundproofing experience and show you all the materials I used to complete my project. You’ll also be able to see and hear the sound reduction results in a number of Youtube videos I’ve created.

So let’s get going!

Part 2 - The Room

From all my soundproofing research I determined the best chance at getting decent sound reduction would be to construct a room inside a room. Working with a blank canvas (unfinished basement) I was able to plan and design the ideal room for my specific needs. Unfortunately if you are currently living in an apartment or renting your home, this may not be an option. That doesn’t mean it’s game over as there are sound reduction materials that you still may be able to use. However I’ll focus on my setup and show you exactly what I did.

Room inside a Room

Room inside a room framing

The idea with a room inside a room is that you actually frame two separate walls. This allows an airgap between that reduces sound significantly. I chose to leave a 6” gap between my walls. The inner room dimensions ended up being 12’ x 8’. I’ll admit it’s a little bit small and I probably should have gone larger, but it’s not uncomfortable for one person. When you decide to plan the size of your outer walls remember to take into account that you will be losing some of that space to the second wall. A room inside a room is a great first step. Now let’s move on to the materials I used to finish the room.

Part 2 - The MATERIALS

I spent a great deal of time planning the materials to be used before beginning my construction phase. I’m sure there are even more options out there today, but at the time I was fairly limited with the choices of soundproofing brands.

Solid Core Doors

A lot of sound can be transmitted through a regular door. Most doors inside a home are hollow and don’t provide much help in preventing sound transmission. I chose to install a brand of solid core door called Safe ‘N Sound. This will greatly reduce the sound that is passing through, but it must also be used with a combination of well installed weather stripping. Just picture the materials that are used around the frame of an outside facing door. I used the same materials and it made a snug fit. The way to ensure your weatherstripping is properly installed, turn off the lights and use a flashlight to see if you can spot any light leaking through the door.

Weatherstripping is one of the most important parts of the soundproofing installation.

Wall Insulation - Go with Mineral Wool

Roxul Safe n’ Sound insulation

Next let’s talk about the materials that I used inside the walls. I chose Roxul Safe n’ Sound insulation. Most people can picture pink fiberglass insulation inside a wall. Although there is nothing wrong with using that type of insulation, there are a few reasons that it is not effective for reducing sound. Fiberglass insulation can be compressed and is less dense than mineral wool. This alone will make it less effective and at blocking sounds. I found the Roxul Safe ‘N Sound really easy to work with. It’s more rigid and cuts well into a desired shape. The added benefit to mineral wool is that it won’t absorb moisture and is fire resistant. So I definitely would recommend it for soundproofing. If you can’t find the Roxul brand where you live, at least try to find an equivalent brand that used mineral wool.

Electrical Outlets - Seal the Gap

Most people won’t even think of this part of the soundproofing. The electrical outlet boxes provide a great space for sound to escape and enter. I used a product called Total Seal Putty Pads. They came in a pack of six and feel just like plasticine. I pad will fit perfectly over the pack of an electrical outlet and block the sound. In addition to providing sound reduction, they also provide a level of fire resistance. These pads are water based and will not dry out and crack like regular clay or plasticine eventually would. Because they stay soft you are free to easily remove them and reuse them if needed.

The Walls

When I was researching drywalling options, there were only two main options on the market. There was a brand of special drywall called QuietRock. I believe it’s more readily available today, but it wasn’t available for me locally at the time. The other popular and less expensive was to use two layers of regular drywall and a product called Green Glue between the layers. I don’t know the science behind it, but they claim the damping glue would convert soundwaves to heat. So I installed two layers of drywall on the walls and ceilings. However before installing the ceiling drywall, there was one more component to consider.

Whisper Clips + Furring Hat Channel

You might be reading this and asking what do those words even mean? The idea is that if you install your drywall directly to the ceiling joists, a lot of sound will transmit through the floor from above. If you install whisper clips to the joists, and the run furring hat channels, you decouple the drywall from the joists. The drywall is now installed into the furring hat channels and not directly into the joist wood. Take a look at the photos on this page to get a better idea of what I’m talking about.

Metal Duct Pipes Are Your Enemy

If you happen to have any metal duct work above you in your ceiling, you will want to wrap that metal. I used a product called Frost King Foam and Foil duct Insulation. It’s very important that you don’t overlook this step. There’s also a rubber paint solution available on the market, but I found the foil insulation really easy to cut and install. You also didn’t need to wait for it to dry.

Whisper clips allow you to suspend the ceiling from the joists. Frost King Foil is wrapped around the duct work in the ceiling.

Mind the Gaps

Once the drywall was installed, there’s still gaps between all the corners of the room. I used an acoustic sealant called SilenSeal. It’s made by the same company at Green Glue. The acoustic provides that final barrier in your room. Much like the outlet putty, the sealant doesn’t dry and wear out.

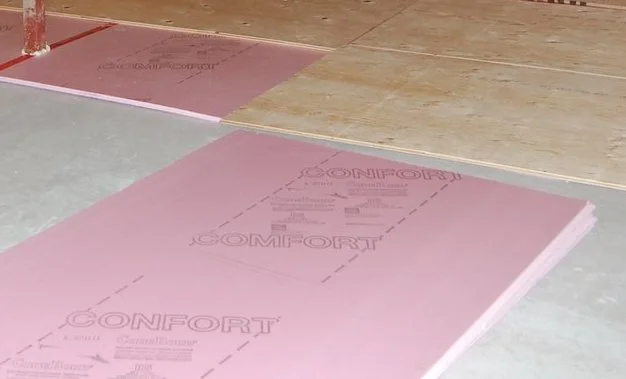

Flooring

Now because my room was constructed in my basement, I didn’t put much thought into soundproofing the flooring. My floor consisted of install 1” pink rigid foam over the cement, then 5/8” tongue and groove plywood. To finish the floor I used a laminate flooring from my local Costco. If I had been building this room on required floor soundproofing, I would have looked at a product called mass loaded vinyl.

Part 3 - The RESULTS

Now it’s great to have a plan for all your soundproofing, but it’s the final results that matter. You can take my word for it that the sound reduction worked extremely well, but how about you see and hear the results for yourself. I’ve created a series of videos that showcase exactly how well my soundproofing worked. Have a look and listen at the video below and let me know what you think!